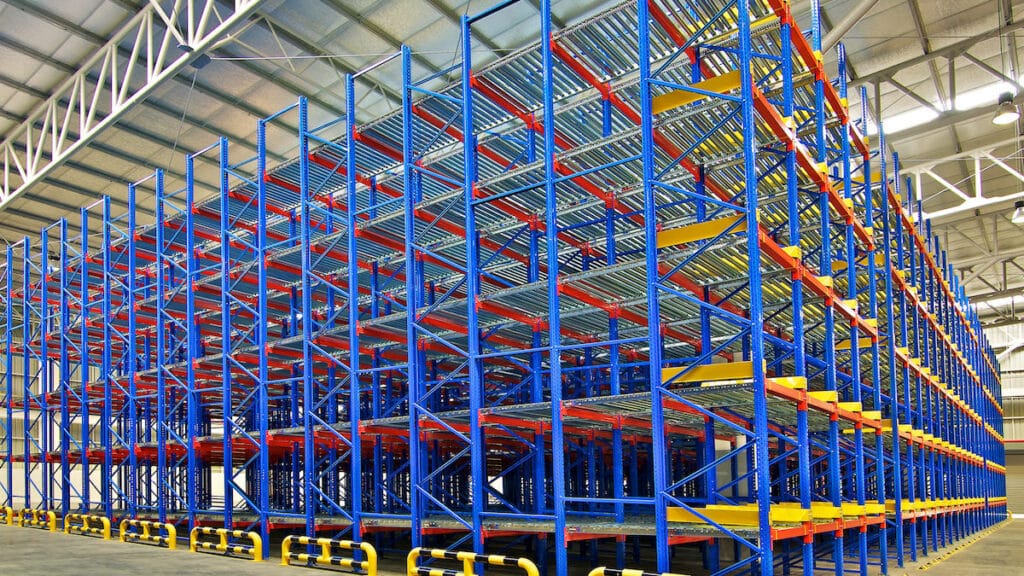

Metal Egypt has a wide range of solutions in pallet racking system, this allows us to reach many sectors and serve many industrial fields. Depending on the customer’s aim, we provide the pallet racking in both first in first out (FIFO), and first in last out (FILO) for picking up the pallet.

Advantages of Pallet racking system:

Doubling the capacity of the warehouse:

By using up the free space in the place by thoroughly designing the warehouse layout and optimizing the utilization of available space, it becomes possible to double the capacity of the warehouse. This involves strategically planning the placement of racks, shelves, and storage systems to make efficient use of every square foot, ensuring that no space is wasted. More Flexibility in operating and handling.

More flexibility in operating and handling:

Increasing the warehouse capacity enhances flexibility in operations. With more space, it becomes easier to accommodate varying storage needs, handle larger volumes of inventory, and adapt to changes in demand. This flexibility allows for smoother operations and improved responsiveness to customer needs.

Direct access to each pallet in the warehouse:

improve the capacity of the warehouse can be achieved by implementing storage systems that allow for direct access to each pallet. This can be accomplished through the use of selective pallet racking or other similar systems. Direct access eliminates the need to move multiple pallets to reach a specific one, saving time and effort in inventory retrieval and improving overall operational efficiency. Simplicity for stock and inventory control

Simplicity for stock and inventory control:

Increasing warehouse capacity can simplify stock and inventory control processes. With more space available, it becomes easier to organize and categorize inventory, making it simpler to track, monitor, and manage stock levels. This simple way leads to improved accuracy in inventory control, reduces the chances of stockouts or overstocking, and enhances overall efficiency in managing stock and inventory.

Reduced handling, transport, and storage costs:

Doubling the capacity of the warehouse can lead to significant cost savings in handling, transport, and storage. With more space available, there is a reduced need for stacking and double-handling of goods, which minimizes the risk of damage and lowers labor costs. Additionally, optimized storage systems and efficient space utilization can result in better inventory management, reducing the need for off-site storage or additional warehouse rentals

Types of pallet racking systems:

Double deep pallet racking

This system involves placing two rows of pallet racks back-to-back. This configuration allows for higher storage density but may require specialized forklifts to reach the inner pallets.

Wide aisle pallet racking

This is the “standard” pallet racking system which has been used in warehouses across the globe for decades. Within this system, each pallet is individually supported and independently accessible.

Narrow aisle

Designed for narrow aisles, this system optimizes warehouse space by reducing aisle width. Specialized forklifts are required for maneuvering within these narrow aisles. In this type of pallet racking system, we use a width of 1.5 meters to 2.5 meters in aisles compared to the standard pallet racking which has a width of 3 meters to 4 meters.

Drive-in the racking system. (LIFO) method

This pallet racking system method is proper warehouses that contain high volumes of the same type of products. Metal Egypt can provide a design for the place that optimizes the warehouse. Drive-in pallet racking consists of lanes equipped with horizontal rails that run to the full depth of the rack. The system can store up to 10+ pallets deep per lane with Last-in / First out method

Drive through pallet racking system. (FIFO) method

Unlike the drive-in racking system, the applied method in Drive-through is First-in / First-out method

-

Cantilever

Cantilever racks are used for the storage of long and bulky items, such as pipes, lumber, or steel. These racks have arms that extend from vertical columns, providing easy access and visibility to stored items.

-

Shuttle

Shuttle pallet racking involves the use of automated shuttle vehicles to move pallets within the rack system. This system increases efficiency and throughput as it minimizes the need for forklifts to enter the racks.

Before designing your pallet racking system and developing the optimal warehouse layout design, you usually need to make business decisions concerning your operation. We’ll help you assess your current space and determine whether you’ll need to upsize, downsize, or simply make better use of the space you’re in now.

Don’t hesitate to ask about our free visit to your site, as our engineers can help you select the proper type of pallet racking and provide the CAD design.

Each of these pallet racking has its advantages and is suitable for specific storage requirements. The choice between them depends on factors such as the type of goods stored, warehouse space, and the desired method of inventory retrieval.

Pricing factors

- Type of Racking System

- Size and design

- Material and Quality

- Additional Features and Accessories

- Installation Costs

- Location and Shipping

Before designing your pallet racking system and developing the optimal warehouse layout design, you usually need to make business decisions concerning your operation. We’ll help you assess your current space and determine whether you’ll need to upsize, downsize, or simply make better use of the space you’re in now.

Get in Touch now and don’t hesitate to ask about our free visit to your site, as our engineers can help you select the proper type of pallet racking and provide the CAD design.