Semi-automated storage systems

HomeSemi-automated storage systems

Semi-automated warehouses

F

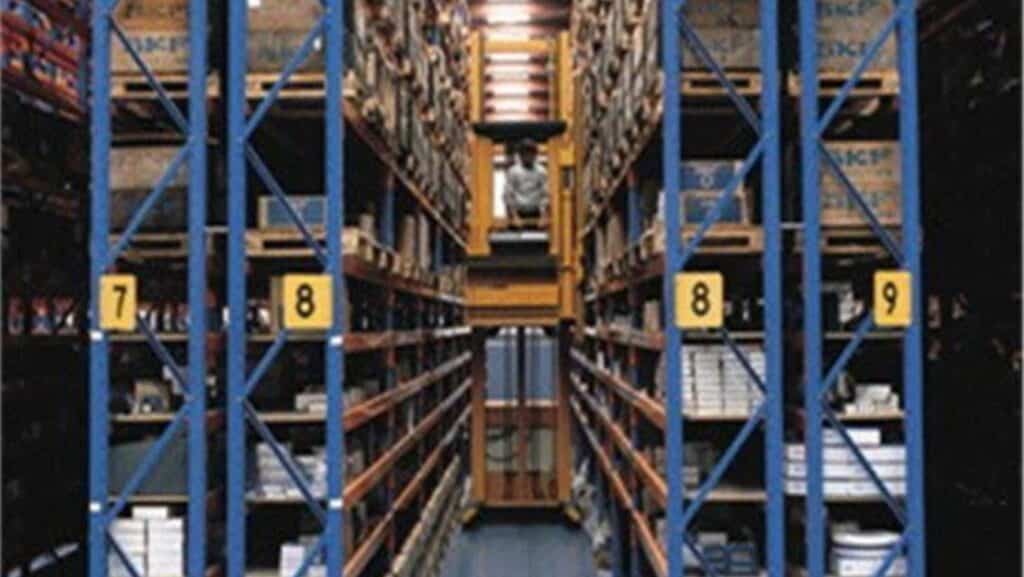

Semi automated warehouses is an integration of the technology into the warehouse industry. Semi automated systems are high density storage systems that allow you to store multiple pallets in a very deep lane configuration. The system also gives you the flexibility of retrieving pallets from any lane with a shuttle device. The pallets are completely loaded and offloaded by the radio transmitter controlled by the warehouse assistant. We recommend this system for the warehouses that have continuous operation.

Engineers in Metal Egypt will recommend for you how to optimise your space in the warehouse using pallets shuttles. Moreover they will train your warehouse managers on how to use the shuttle racks.

F

Features :

F

- More safety

- Less labour

- Technology integrated

- Easy to understand. Less complex

- More productivity

- More storage density

- Decreasing the human error

- Less time in handling

Semi-Automated Storage Systems Standards

| Location ID | System Type | Aisle Width (m) | Rack Height (m) | Number of Levels | Pallet Capacity per Level | Total Pallet Capacity | Automation Type | Storage Status | Notes |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Shuttle System | 2.5 | 10 | 5 | 20 | 100 | Pallet Shuttle | Available | Requires calibration |

| 2 | Carton Flow Rack | 2.0 | 8 | 4 | 30 | 120 | Gravity-Based | Full | |

| 3 | Mobile Racking System | 1.8 | 12 | 6 | 15 | 90 | Motorized Mobile Base | Available | |

| 4 | Semi-Automated Stacker | 3.0 | 15 | 7 | 25 | 175 | Guided Stacker Equipment | Maintenance Needed |