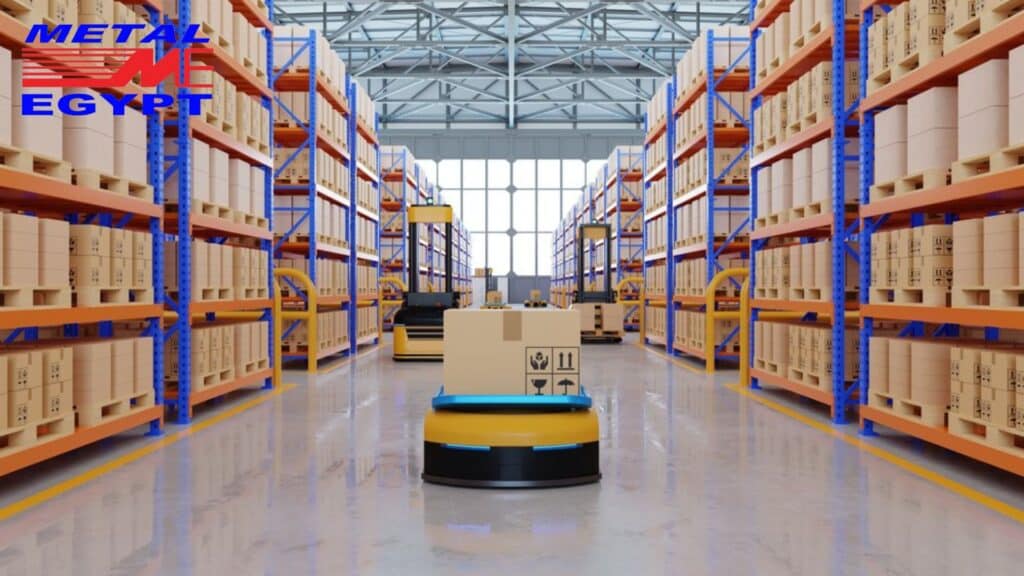

Warehouse shelving solutions encompass diverse storage systems designed to organize and store goods efficiently within industrial facilities. These systems come in various forms, including boltless shelving, pallet racking, and cantilever racks, each tailored to specific storage requirements, We will discuss all of these types and information about them so that you can choose what suits your needs.

warehouse shelving solutions types

Let’s explore the different types of warehouse shelving solutions in detail:

- Long Span Racking:

- Long span racking allows storage of goods with diverse shapes and sizes, from small to medium quantities.

- It is widely used across various industries for storing both small parts and large items.

- Designed for direct order picking, following the “goods-to-person” principle.

- Offers flexibility in application and can be easily adjusted.

- Pallet Racking:

- Pallet racking is ideal for storing palletized goods.

- Commonly used in distribution centers, warehouses, and manufacturing facilities.

- Provides efficient use of vertical space and easy access to pallets.

- Types include selective, drive-in, and push-back racking.

- Cantilever Racks:

- Cantilever racks are designed for long, bulky items like pipes, lumber, and steel.

- Arms extend from vertical columns, allowing easy access and storage.

- Suitable for hardware stores, lumberyards, and construction material storage.

How to choose the right type for your needs?

Selecting the right warehouse shelving solution depends on several factors. Let’s break it down:

- Storage Needs:

- Consider the types of items you’ll store. For small parts, long-span racking is versatile. For palletized goods, pallet racking is ideal.

- If you handle long, bulky items (like pipes or lumber), cantilever racks are suitable.

- Space Availability:

- Assess your warehouse space. Pallet racking maximizes vertical storage, while long-span racking offers flexibility.

- Cantilever racks require open space for long items.

- Accessibility:

- Pallet racking provides easy access to pallets.

- Long-span racking allows direct order picking.

- Cantilever racking offer accessible arms for long items.

- Budget and ROI:

- Consider costs and long-term benefits. Each system has different price points and efficiency gains.

Remember,We also provide cable tray to ensure the protection of wires and systems. tailor your choice to your specific needs. If you need further guidance, feel free to contact us and ask!

What is special about Metalegypt warehouse shelving solutions?

Metalegypt offers top-quality warehouse storage solutions, specializing in shelving, racking, and Cantilever racking systems. With 16 years of experience, We provide tailor-made solutions for all your storage needs. Our product range includes pallet-racking systems, drive-in systems, wide long-span, Mobile shelving system, office shelving, and more. If you’re looking for reliable warehouse storage solutions in Egypt, Metalegypt is a great choice!

What material do we use in shelving units?

When it comes to constructing warehouse shelving units, the choice of materials plays a pivotal role. Typically, industrial shelving is crafted using a combination of metal and wood. The primary materials include steel, aluminium, copper, chrome, plywood, koa, and oak.

These materials are meticulously selected for their robustness, durability, and extended lifespan. Steel remains the most prevalent choice in the industry, closely followed by copper and aluminium. Additionally, warehouse shelving systems come in various configurations, such as Long Span Racking for accommodating large article ranges and Mobile Shelving for compact archive storage. These systems optimize space utilization, enhance operational efficiency, and ensure secure and accessible storage solutions for businesses.

Best warehouse shelving solutions in 2024

Certainly! As we step into 2024, the landscape of warehouse shelving solutions continues to evolve. Here are some trends and top solutions to consider:

- E-commerce Dominance: With online sales surging, warehouse managers must prioritize e-commerce fulfillment. Solutions like carton flow, dynamic industrial shelving, and pallet flow are essential. These systems optimize space, enhance accessibility, and improve order fulfillment.

- Space-Saving Innovations: Mobile shelving units and vertical lift modules (VLMs) maximize existing floor and ceiling space. Cross-docking, where goods move directly to outbound gates, minimizes storage time.

- Automation: Organizations are adopting technologies like WMS/WES/WCS software, radio frequency picking, conveyor systems, and robotic cube storage. Automated storage and retrieval systems (ASRS) also play a key role.

- Exception Management: Better product labeling, organization strategies for Pallet racking system, and efficient exception handling help warehouses respond swiftly to issues.

In this dynamic environment, staying adaptable and embracing innovative solutions is crucial for efficient warehouse operations.